Warehouse Safety Updates: Working Safely with Robots and Preventing Lifting Injuries

June 16, 2022:An exciting new innovation at our Statesville, North Carolina facility this past quarter was the deployment of LocusBots in distribution. A key safety advantage of using robots is reducing the number of industrial vehicles in the warehouse and stock chaser-related injuries. To help team members work safely in the new environment, new trainings, safety protocols and signage has been introduced in the facility. A big thank you to our Safety Committee members, who provided numerous suggestions to help improve safety, such as ensuring LocusBots do not block evacuation paths or fire extinguishers.

Preventing lifting injuries remains a key focus for all departments in the warehouse. To continue to promote safe lifting techniques, we recently created a training video for new hires with examples of ergonomic risk factors that may be encountered at work, and the “do’s and don’ts” of lifting. Thank you to our supervisors Mark, Jay, and Pachia for modeling safe and unsafe practices in the video!

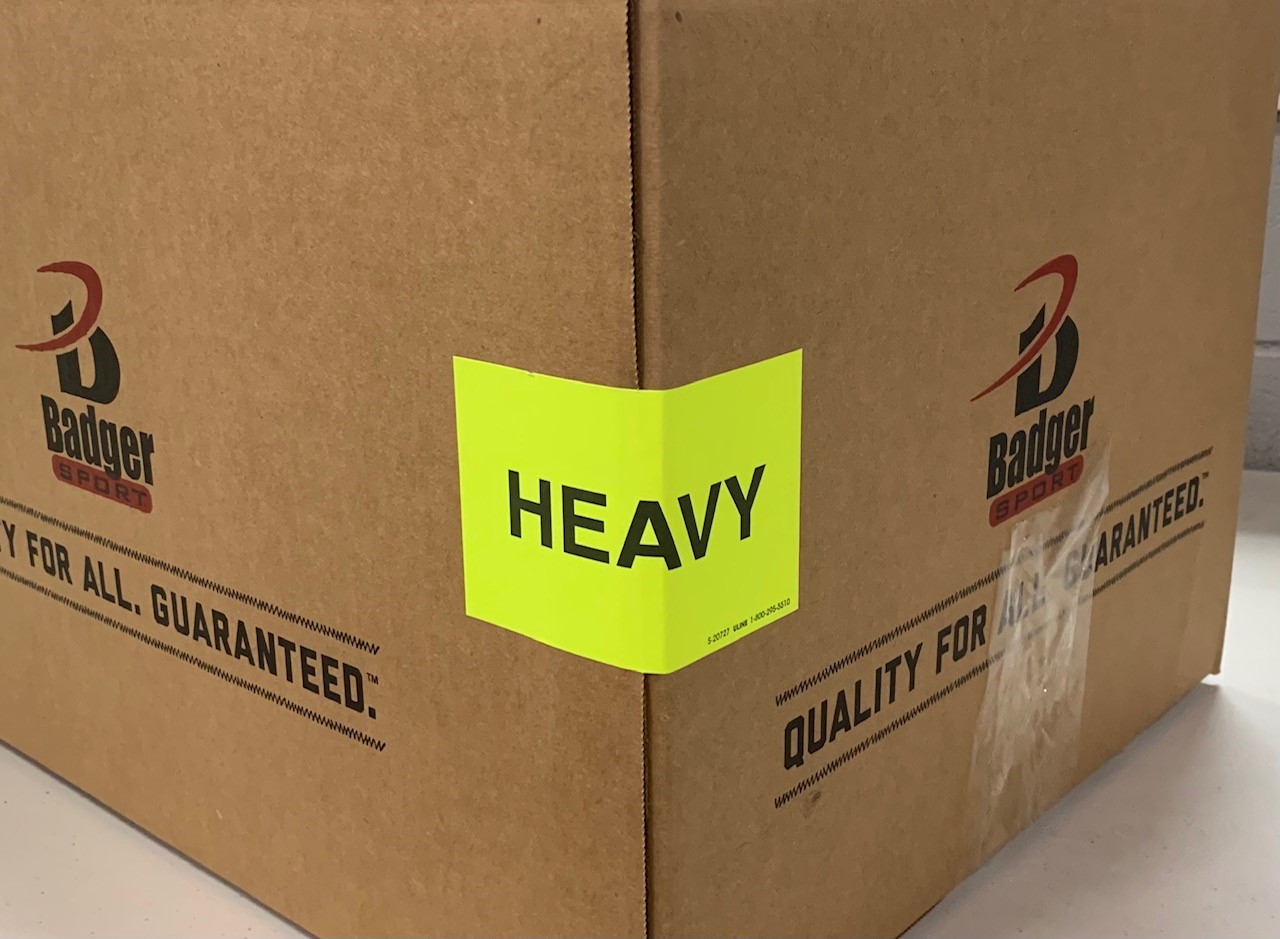

In addition, to reduce the risk of lifting-related injuries, we now require our suppliers to label boxes that exceed 35 pounds with yellow “Heavy” stickers. Employees are reminded to use a Team Lift when lifting a heavy or awkward load. Using proper lifting techniques and body postures can help prevent muscle strains, back and shoulder injuries.

In addition, to reduce the risk of lifting-related injuries, we now require our suppliers to label boxes that exceed 35 pounds with yellow “Heavy” stickers. Employees are reminded to use a Team Lift when lifting a heavy or awkward load. Using proper lifting techniques and body postures can help prevent muscle strains, back and shoulder injuries.